HEAT AND COOLANT – TRACED HOSE

MATERIAL AND DESIGN

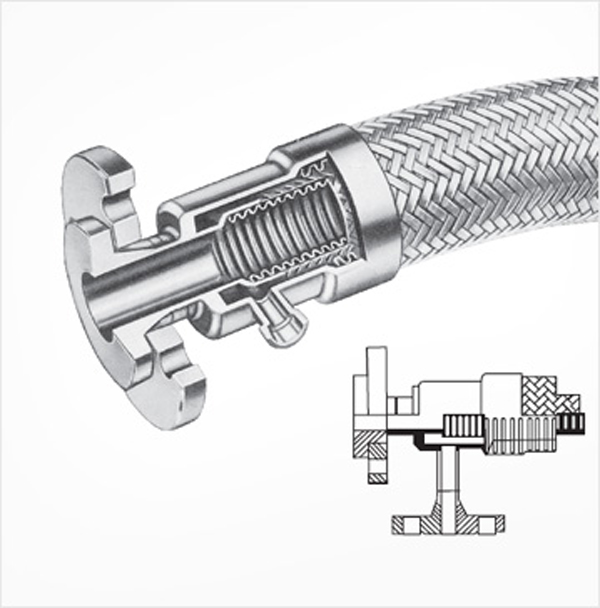

For the Internal hose and the Jacketed hose, our stainless steel corrugated hose is used with stainless steel braiding.

SS304/304L/316/316L/321

SS304/304L/316/316L

400°C max. (600° C is possible as a special design).

-

When ordinary insulation is not sufficient for certain applications, or when specific minimum temperatures are needed to convey viscous substances, traced piping is generally used; this consists of two tubes, one inside the other, with various differences in cross-section.

One of the tubes, generally the inner one, carries the medium, and the other one carries a heating or cooling agent; sometimes it is the other way around. In other cases, the external tube is used as a safety measure.

Occasionally, such traced piping has to be flexible; for such applications we supply our Jacked hose.

Its high flexibility makes this hose very suitable for angular and lateral (offset) movement. The Jacketed hose is pressure and vacuum proof and due to the materials used for its manufacturing. it is resistant to temperature and corrosion. The large surface area of the corrugated section results in particularly high heat transfer efficiency, the hose combining the functions of a flexible conduit and a highly efficient heat exchanger in the simplest possible form.

The JACKETED Hose is suitable for many different purposes.

As a heat-able element the hose is mainly used in the chemical , pharmaceutical, oil and civil engineering machinery industries to convey viscous or temperature – sensitive media, such as

- Bitumen

- Fats

- Naphthol

- Phenol

- Polyster

- Mercury

- Sulphur

- Fatty acids

- Paraffin

- Tar

- Chlorophenol

- Chocolate

- Heavy fuel oil

- Naphthalene

- Explosive (TNT)

- Thermosetting Plastic

- Dimethyl terephtlate (DMT)

- Synthetic resin

- Organic liquefied materials

- Phthalic acid, waxes and others

The heating agents used are hot water, steam, heat transfer oils or other heat transfer agents.

For cooling, water is the most common agent.